Within this section

This section was last updated in June 2020

A new stochastic approach of assessing the oil sands has been developed to capture subsurface variability. The aim of this new methodology is to increase accuracy and transparency and to create a framework that allows oil sands reserves to be updated on a yearly basis, consistent with Inter-Provincial Advisory Committee on Energy (IPACE).

Oil sands areas

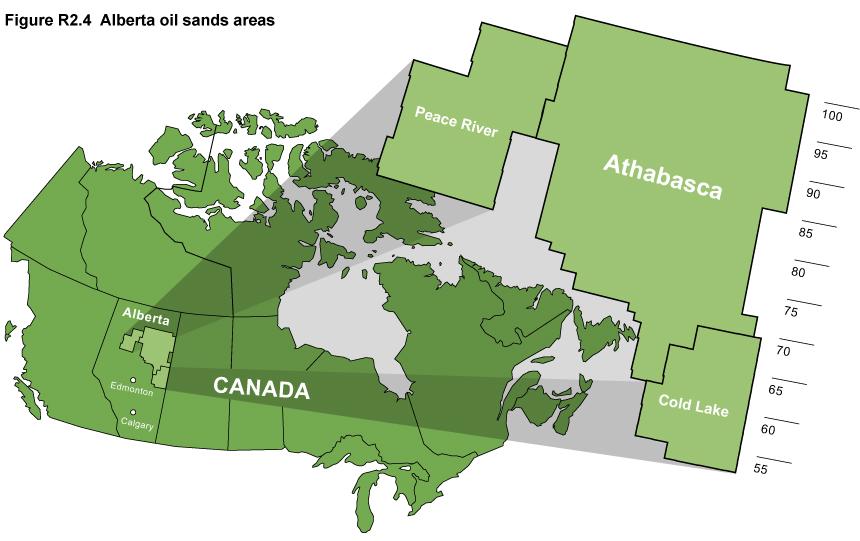

There are three Alberta oil sands areas: Peace River, Cold Lake, and Athabasca. The largest oil sands area is the Athabasca, covering over 93 000 km2, with bitumen deposits hosted predominantly within the Wabiskaw Member and McMurray Formation. The Peace River oil sands area covers over 29 000 km2, with bitumen deposits mainly within the Bluesky and Gething Formations. The Cold Lake oil sands area is the smallest, covering nearly 18 000 km2, with bitumen deposits mainly within the Clearwater Formation (Figure R2.4).

Oil sands

Oil sands are a mixture of sand, clay, water, and bitumen. Bitumen is extremely viscous (up to four times more viscous than peanut butter) and does not naturally flow. Heat or lighter hydrocarbons are added, lowering the viscosity of the bitumen and allowing it to flow. To produce bitumen, methods such as mining, steam-assisted gravity drainage (or SAGD, mainly in Athabasca), or cyclic-steam stimulation (or CSS, mainly in Cold Lake) must be used. At depths shallower than 75 m, oil sands are extracted in open-pit mining operations. Beyond this depth, clearing overburden becomes too costly, and bitumen is recovered subsurface by in situ methods using steam or steam with solvents.

Steam-Assisted Gravity Drainage (SAGD)

SAGD is a process that uses steam to heat the reservoir to reduce the viscosity of the bitumen and requires drilling at least two horizontal wells: an injector on top and a producer below, generally 5 m beneath the injector. The upper well injects steam into the reservoir, creating a steam chamber and heating the bitumen up to 230oC, reducing its viscosity and allowing it to flow.

With the help of gravity, the now-mobile bitumen and condensed steam flow to the producer well and are pumped to the surface for transport, separation, and partial upgrading. Laterally continuous, horizontal mud beds act as barriers to the steam chamber, slowing or completely stopping its growth. SAGD is not currently economically viable for reservoirs less than 7 m in net pay thickness.

Upper or lateral water and gas reservoirs, which are in association with the bitumen reservoirs, may act as thief zones (fluids, other than bitumen, within the reservoir that steal steam energy) to the steam chambers.

Cyclic-Steam Stimulation (CSS)

Cyclic-steam stimulation (CSS), also known as “huff and puff,” consists of three stages: injection, soak, and oil production. Steam is injected into a well at 300 to 340°C for weeks to months to heat the oil in the surrounding reservoir, recovering about 20% of the original bitumen in place (OBIP). In comparison, over 50% of OBIP is recovered using SAGD.

CSS is predominantly a vertical-well process but could be applied on multilateral horizontal legs by alternating steam injection with producing heavy oil and steam condensate. CSS works best in thick pay zones (>10 m) with high-porosity sands (30%).