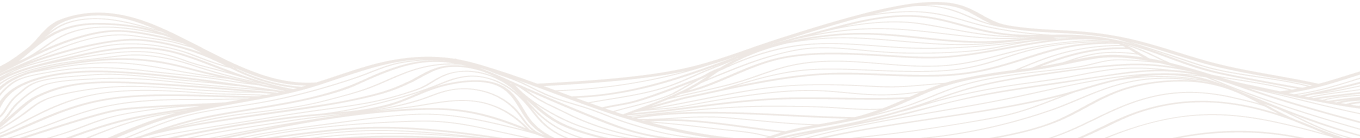

Carbon capture, utilization, and storage (CCUS) refers to a range of technologies and processes that capture carbon dioxide (CO2) from sources such as industrial facilities, transport the CO2 through pipelines, then inject it into deep subsurface geological formations (e.g., saline aquifers or depleted oil and gas reservoirs) for permanent storage. CCUS technologies are recognized by the Government of Alberta as effective tools for reducing emissions and mitigating the effects of climate change.

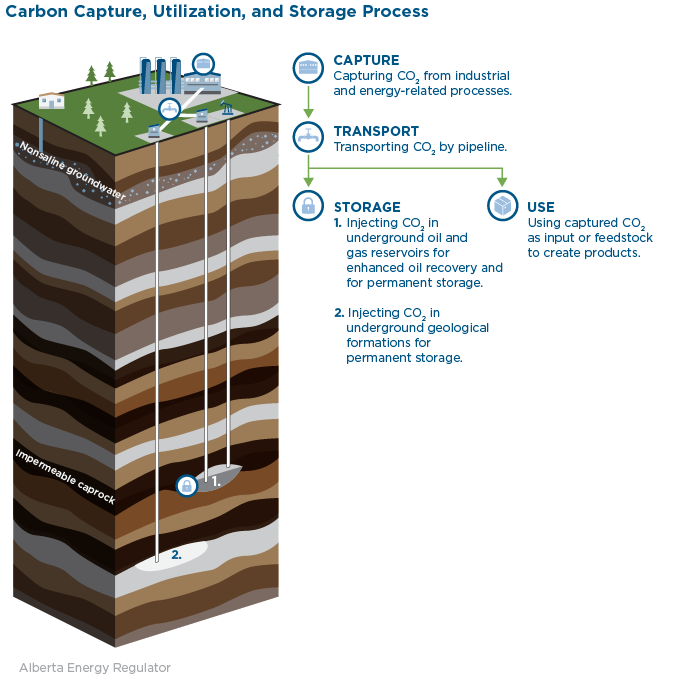

The AER regulates two types of CCUS processes:

- Carbon Capture and Storage (CCS)

CCS projects are also referred to as CO2 sequestration schemes. A CO2 sequestration scheme is the permanent storing and trapping of CO2 in an approved subsurface formation. This is also called dedicated storage. A carbon sequestration tenure or agreement from the Government of Alberta is required if a company wants to apply for a CCS project. An example of a CO2 sequestration project that has received AER approval is the Quest CCS project operated by Shell.

- Carbon Capture, Utilization, and Storage (CCUS)

CCUS projects are also referred to as CO2 enhanced oil recovery (EOR) and storage schemes. Using CO2 in EOR schemes improves the production of residual oil and also has the effect of permanently sequestering some CO2. We have been regulating CO2 EOR schemes for more than 25 years. CO2 EOR and storage schemes are expected to store large volumes of CO2 to help reduce greenhouse gas emissions. An example of this is Alberta Carbon Trunk Line operated by Enhance Energy Inc.

Captured CO2 can also be used as an input or feedstock to create products such as cement. The AER does not oversee this part of the process.

Our subsurface requirements for CO2 schemes are set out in Directive 065: Resources Applications for Oil and Gas Reservoirs, Units 2 and 4, as illustrated below.

Carbon Capture Facility

The overall CCUS process begins with the installation of CO2 capture technology, which can occur at an industrial emission source (e.g., upgraders, in situ central processing plant) or capturing CO2 directly from the atmosphere using direct-air capture technology.

The AER is responsible for CO2 capture technologies associated with AER-regulated facilities (e.g., oil sands upgrader).

Alberta Environment and Protected Areas (AEPA) is responsible for CO2 capture technologies associated with AEPA-regulated facility (e.g., chemical manufacturing plant, cement manufacturing plant).

Operators planning to install and integrate CO2 capture technology with an approved AER-regulated facility need to file an application to amend their existing approvals. Such applications follow the AER’s sector-specific Application Processes for oil sands (mining and in situ), coal mining, and oil and gas activities.

How are CO2 schemes regulated under provincial legislation?

The Mines and Minerals Act states that the Crown owns the pore space for CO2 sequestration schemes, may enter into tenure agreements with respect to its use, and establishes the framework for liability transfer.

For information on carbon sequestration tenure, please visit the Government of Alberta’s Carbon capture, utilization and storage – Carbon Sequestration Tenure webpage.

The Oil and Gas Conservation Act (OGCA) permits the AER to approve CO2 schemes if CO2 injection will not interfere with

- the recovery or conservation of oil and gas, or

- an existing use of the underground formation for storing oil and gas.

The Water Act enables the AER to issue Water Act approval if required for surface water or groundwater.

The Environmental Protection and Enhancement Act (EPEA) regulations governing oil and gas, coal, and oil sands activities also can apply to CCS projects, including for conservation, reclamation, and closure of wells and pipelines, and remediation of contaminated sites.

Surface rights for CO2 sequestration and CO2 EOR and storage projects are managed the same as for other oil and gas developments in the province, through the Public Lands Act, Surface Rights Act, and the OGCA.

Alberta Energy and Minerals issues the tenure rights for storing CO2. Further information on tenure management can be found on the government’s Carbon Sequestration Tenure Management webpage. Alberta Environment and Protected Areas enables the generation of carbon credits through the Alberta Emission Offset System and the generation of emissions performance credits under the Technology Innovation and Emissions Reduction Regulation.

The AER regulates all energy-related aspects of carbon capture and oversees measurement, monitoring, and verification plans, and closure plans. The Carbon Capture Regulation and Responsibilities brochure provides information on carbon capture regulation and responsibilities.

Our Requirements

We regulate the energy-related facilities that capture CO2, the pipelines that transport the CO2, and the subsurface injection activities.

We have several directives, listed below, that set out the requirements for CO2 schemes across their life cycle. These requirements range from how wells are to be used to inject CO2 into subsurface formations to where CO2 can be safely stored subsurface.

| Directive | Description |

|---|---|

| Directive 020: Well Abandonment | Requirements for abandonments, casing removal, zonal abandonments, and plug backs. |

| Directive 023: Oil Sands Project Applications | Requirements for filing application for in situ and surface or underground mining operations. It also sets out application requirements for oil sands processing plants and covers bitumen extraction facilities, refineries and upgraders, and certain gas processing facilities. |

| Directive 051: Injection and Disposal Wells – Well Classifications, Completions, Logging, and Testing Requirements | Requirements for wellbore design, wellbore integrity logging, operational monitoring, and reporting of injection wells. |

| Directive 056: Energy Development Applications and Schedules |

|

| Directive 065: Resources Applications for Oil and Gas Reservoirs | Subsurface requirements for CCS and CCUS processes. |

| Directive 071: Emergency Preparedness and Response Requirements for the Petroleum Industry | Requirements for preparing and implementing an emergency response plan. |

| Directive 087: Well Integrity Management | Requirements for testing, reporting, and repairing isolation packers, surface casing vent flows, gas migration, and casing failures. |

| Guide to Content for Energy Project Applications | This guide applies to the preparation of applications for all energy projects identified in Schedule 1, Divisions 1, 2, and 3 of the Activities Designation Regulation and the Responsible Energy Development Act. |

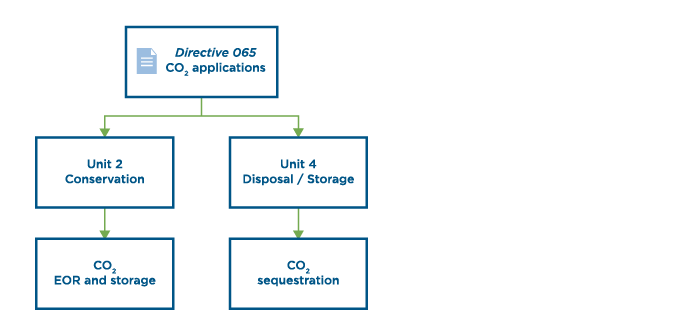

Operators are also required to submit for approval monitoring, measurement, and verification (MMV) plans and closure plans prior to operation, and updated periodically. Additionally, they are required to submit annual reports on their activities.

Compliance and Enforcement

We regularly conduct inspections and audits to make sure that companies are following our requirements. If we find that a company is noncompliant, we will take the appropriate compliance and enforcement actions.

Carbon Sequestration Project Plans and Reports

The oversight of monitoring, measurement, and verification (MMV) plans and closure plans was delegated to the AER by ministerial order on April 25, 2023. The AER updated Directive 065: Resources Applications for Oil and Gas Reservoirs in July 2023 and added the Alberta Energy and Minerals MMV principles and objectives document as an appendix, as the AER now has ownership of this document.

Monitoring and measurement are surveillance activities necessary for ensuring the safe and reliable operation of a CO2 sequestration project. Verification refers to the comparison of measured and predicted performance, which is also known as conformance.

The purpose of a monitoring, measurement, and verification (MMV) plan is to address health, safety, and environmental risks; evaluate sequestration performance; and provide evidence that the site is suitable for closure.

A closure plan describes the activities that will be undertaken to close carbon sequestration operations and facilities. It contains details on wells and facilities monitoring and decommissioning, abandonment, and reclamation activities to provide performance evidence that CO2 will remain in the deep subsurface geological formations.

MMV plans are updated at specified intervals as provided for in the subsurface scheme approval documentation.

Carbon capture and storage project operators must also submit annual reports of their operations, as identified in their specific AER approvals.

The required MMV plans, closure plans, and annual reports for CO2 sequestration projects are found below.

| Operator | Project | MMV Plan | Closure Plan | Annual Report |

|---|---|---|---|---|

| Shell Canada Limited | Quest Project | 2023 PDF | ||

| Enhance Energy Inc. | Enhanced Oil Recovery Initiative/Alberta Carbon Trunk Line | |||

| Bison Low Carbon Ventures Inc. | Meadowbrook Carbon Storage Project |